Murray Anderson was Business Development Manager for Mainzeal Construction Company Ltd in 1986 when he was asked by the Wellington Hospital Board to investigate a possible car parking building to be built on an existing car park site on hospital land.

“Researching the project, we found people were using the hospital grounds to park and ride the bus into the city,” Murray says.

“We came up with a proposal to put up barriers controlling access and to charge for parking within the hospital grounds. Mainzeal was awarded a contract to run the car park on the basis we funded the cost of setting up the carpark.”

The nearby King Edward V11 Memorial Hospital for Children was awaiting demolition and as part of the parking proposal Mainzeal funded and demolished the children’s hospital.

Murray along with a couple of senior hospital board managers walked through the old hospital to see if there was any way of saving a set of Royal Doulton ceramic tiled panels that had been on display on the hospital walls since it opened in 1912. The tiles had been bought from Royal Doulton in London for £817 (equivalent to almost $150,000 in 2020).

Each panel depicted a well-known nursery rhyme and the collection included “Simple Simon met a pie man going to the fair,” “Little Miss Muffett who sat on a tuffet,” “Cinderella in the chimney corner,” and many others.

By the time Murray got there, an attempt had already been made to remove some tiles of the “Hey diddle diddle the cat and the fiddle” panel. The few tiles that had been removed had broken in the process, the rescue had been abandoned and the decision made to send them all to the tip, along with the building demolition materials.

Not yet ready to give up on the salvage challenge, Murray went back to the office to discuss the tiles with Martin Riley, Mainzeal’s Wellington Area Manager. Murray, Martin and Rick Herd, the Project Manager, devised a plan to save the tiles. John contacted Royal Doulton, who sent out a representative from the United Kingdom to assess the tiles. This was fortuitous as Royal Doulton later made an $80,000 contribution toward the cost of saving the tiles.

Now the pressure was on to plan the safe removal of the tiles – which were cemented directly to the structure of the building - to the load bearing unreinforced brick masonry columns and to the walls of the hospital itself.

From previous efforts to remove the “Hey diddle, diddle” mural it was obvious that the tiles were stuck more effectively to the brick structure than the bricks were to each other. The cement paste used to fix the tiles was essentially pure cement and water, while the brick mortar connecting the bricks, contained large proportions of sand and possibly lime as an alternative or supplement to the cement. Water getting in from outside over the years had broken down the brick mortar, particularly on the external surfaces, leaving it soft and crumbly.

“As the tiles couldn’t be removed from the bricks without causing irreparable damage, we had to devise a new strategy. We decided to retain a thin veneer of brick bonded to the tiles, which would then be locked together with concrete to provide a rigid and robust panel for each mural so it could be relocated, erected and enjoyed for years to come.

The challenge was how to remove most of the brick backing and cast a thin structural concrete layer over the remaining brick and tile so as to create a single panel. This could only be achieved by laying the mural face down, removing all but a thin brick veneer from behind and casting the reinforced structural concrete layer over that veneer.

The task of safely laying each mural face down brought its own challenges. The tiles making up each panel were handmade and hand painted before being individually mounted. Each tile had irregularities across the face of the tiles, meaning they were not perfectly flat like a piece of glass. Further complicating the task, the weight of each panel and its brick backing was up to four tonnes. Lowering the panels to a flat position required careful planning to avoid cracking or chipping of the tiles.

To overcome this, Rick says the team fixed a wooden frame to the face of the column on both sides and below the mural with masonry anchors, and put a heavy plywood sheet over that. This left a void of approximately 25mm between the mural and plywood, and this was filled with liquid gypsum plaster (plaster of paris). The plaster then took the shape of each tile, supporting and cradling the entire mural behind the plywood.

“The brick columns and wall were relatively fragile because they were unreinforced and due to the degradation of the brick mortar - essentially creating a stack of relatively loose bricks. Fortunately, the mortar had retained enough compressive strength to hold the tiles in place on the hospital walls,” Rick says.

The plan called for the bricks behind the tiles to be post-tensioned in three dimensions. This was done by diamond cutting 200 wide by 100m deep recesses around the circumference of each brick column directly above and below the tiled mural. Where the panels were on a wall rather than a column, this meant sections of wall either side of the mural had to be cut out and the floor above propped, in effect leaving the murals in place on a column on what was the remnant of the wall.

“One column at a time, four heavy section 150 x 75 steel channels were then fixed into the newly formed recesses, across the interior and exterior channels above and below the mural. These were held in place with eight 20mm diameter high tensile treaded rods, four from inside to outside and four top to bottom,” Rick says. “The nuts on the rods were tightened to compress the bricks together vertically and inside to outside. That is, we had the bricks post tensioned in two directions, vertically and inside to outside. Once rigid we could place another set of four channels and rods laterally across the inside and outside face of the column, two channels and rods top and two channels and rods bottom. These were also tightened in place to compress the bricks behind the column in the third dimension.”

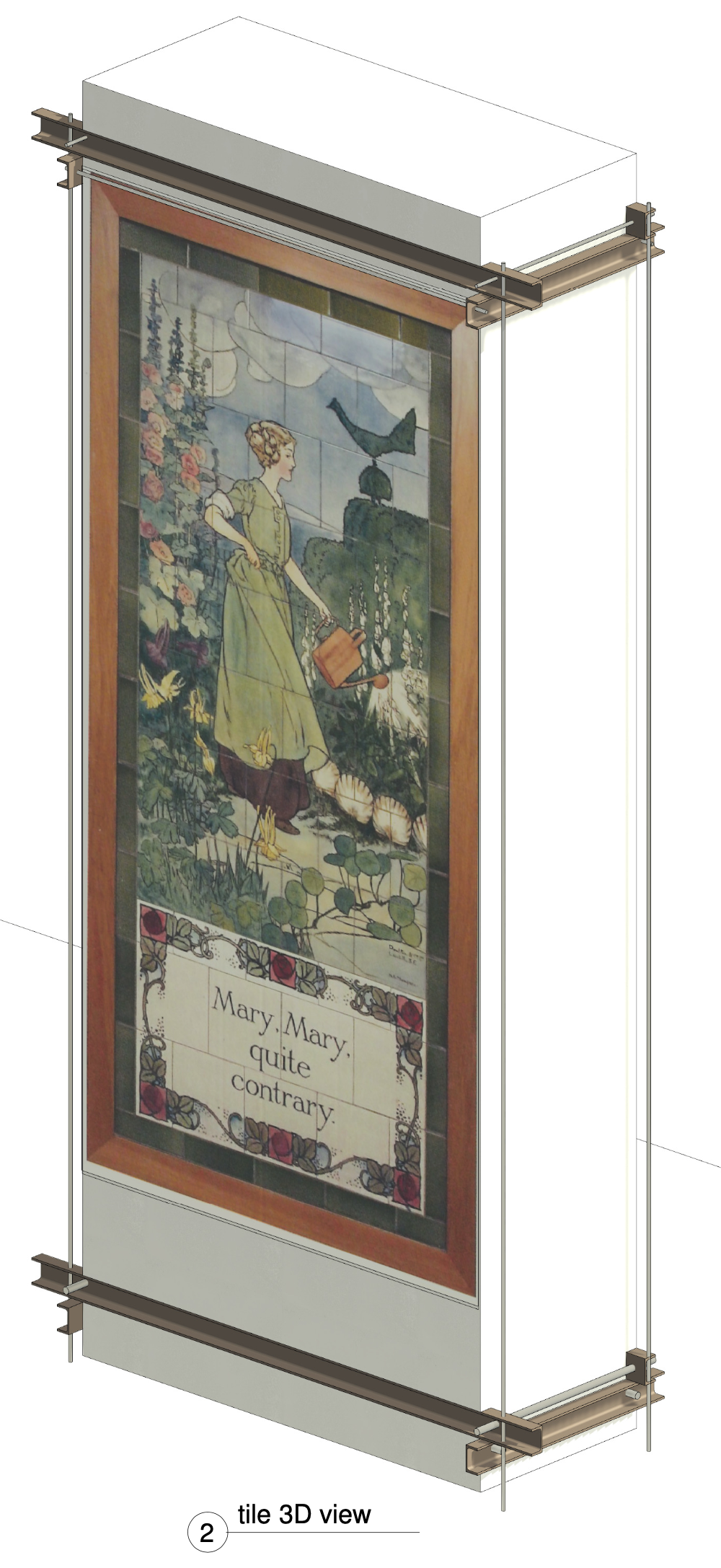

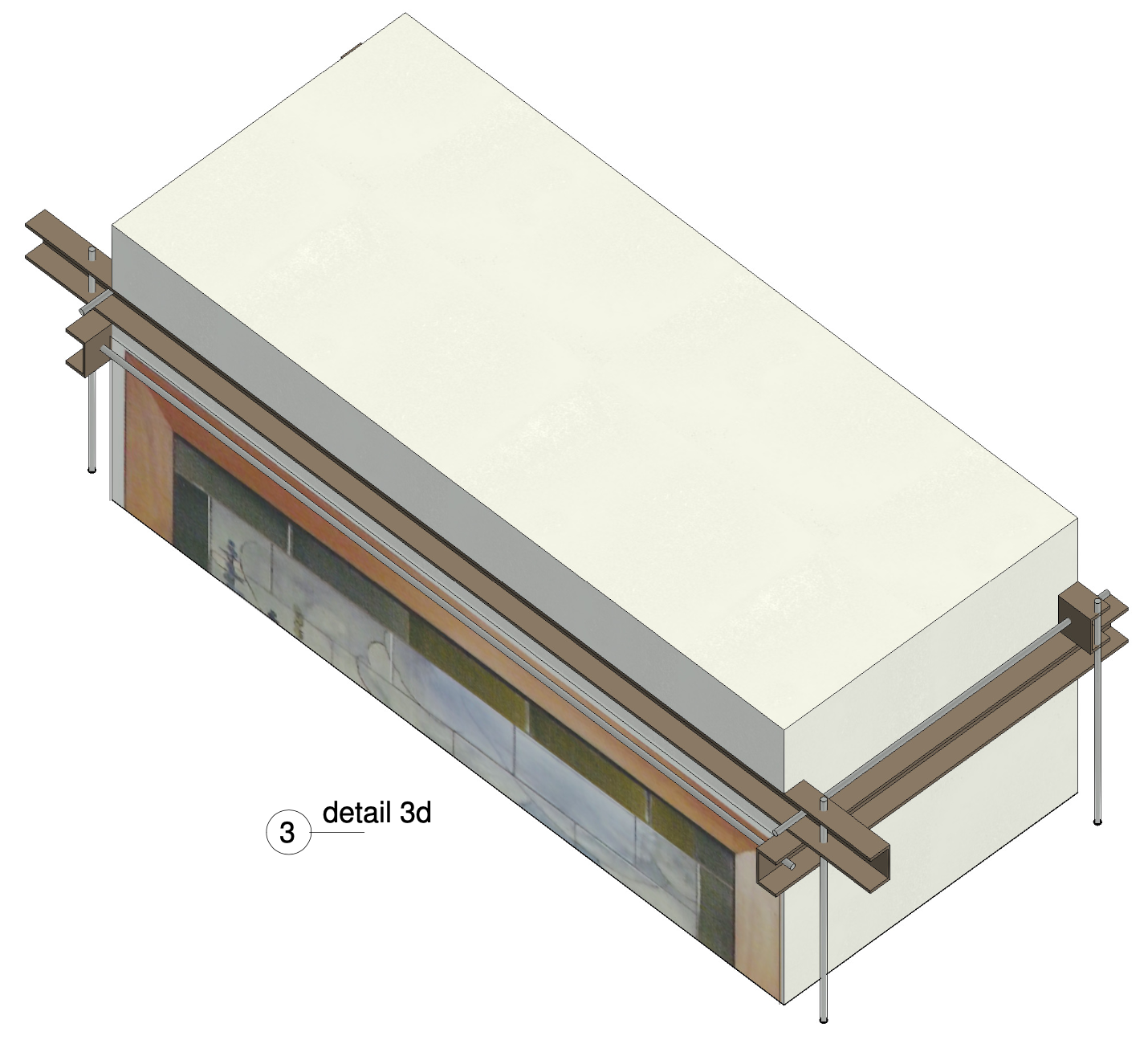

See the drawings below ,,,,,,,,,,,,,,,,,,

Once the bricks behind the column were in compressive tension within the steel cradle frame, the team could prop the floor above on both sides of the mural, and remove the bricks from the column directly above mural. This allowed the mural and its brick backing to be removed from structure of the building using a forklift. The weight of each mural and its brick backing was typically in the range 3.5 - 4 tonnes.

Once removed and clear of the building each mural and its backing were lifted by crane, then gently tilted onto a bed of soft sand, with the mural fully cradled by the plaster and plywood. When it was in the face down position, the steel compression frame could be removed and the loosely held backing bricks removed by hand. Where the mortar held fast, a slow process of diamond cutting the bricks was used until the workers were just one layer or brick behind the mural. At that point a structural concrete layer about 125mm thick was applied over the back of the remaining bricks to lock the bricks and the mural together and create a single, monolithic panel of approximately 1.5 tonnes. This gave each panel the strength and rigidity to be moved and re-installed as required in future.

“I would like to thank Martin Reilly, sadly deceased, Murray Anderson and Royal Doulton for entrusting me with this project,” says Rick Herd. “While not the largest, nor the most complex it has been the most satisfying project I have delivered in my almost 50-year career.”

After decades in storage, the murals are now back on display at Wellington Hospital.

Murray Anderson

return to top of page